mycotopia

MYCOTOPIA was a collab with TU berlin on 3d-printed mycelium components for architectural application (2021)

Column shells generated with the reaction-diffusion algorithm in Grasshopper, 3D printed from PLA © Clara Schmelter de Escobar

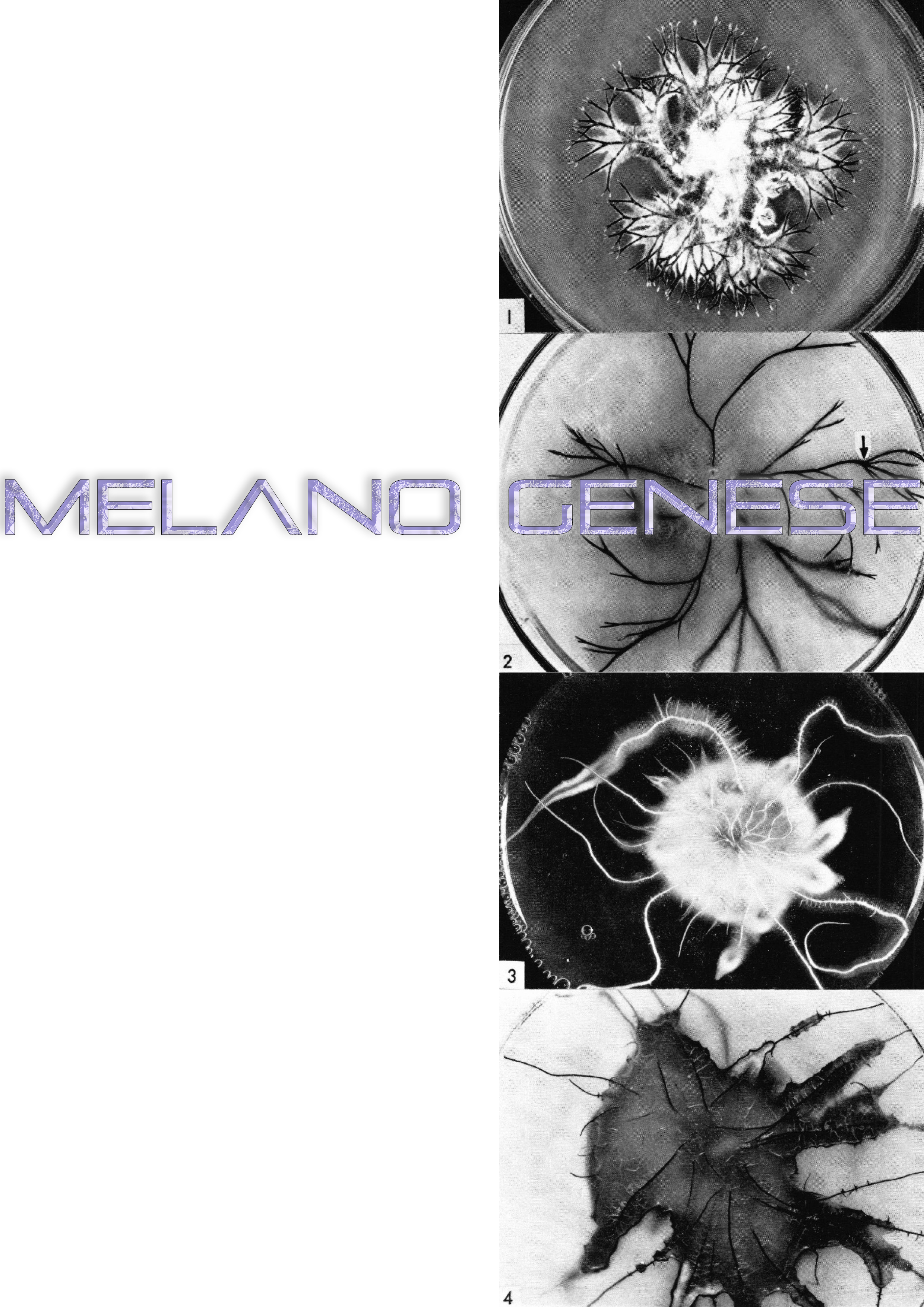

Termite mounds can reach a diameter of up to 30 m and a height of up to 9 m. The insects carry collected plant material into their mounds. There, in an optimally regulated indoor climate, they cultivate a fungus, that processes the material and transforms it into nutrients on which both it and the termites live. In natural additive manufacturing, a special geometry is thus created. Vertical channels promote the convective flow of air and respiratory gases through thermal buoyancy, generated by the funguses metabolic heat. Like a leaf folded in on itself and connected to each other with a uniform thickness of about 4 mm, which probably corresponds to the depth in to which the hyphae can grow effectively, while having access to oxygen. Mycolumn is a collaboration with the Institute for Materials Science & Technologies at TU Berlin. Investigating the hypothesis that an enlarged surface area for fungal gas exchange increases the formation of hyphae, thus maximizing their useful properties as composite materials (Goidea, Ana et. al. Pulp Faction: 3d printed material assemblies through microbial biotransformation, Open Access Fabricate Proceedings Fabricate Conference, pp. 42-49, 2020). As a study, surface enlarged colums shells were 3D printed with porous biopolymers and fillled with substrate and mycelium.